PP Quick Joint Compression Fitting Coupling

Guangdong Yulesun Building Materials Co., Ltd.- Material:Plastic

- Connection:Female

- Head Type:Round

- Flexible or Rigid:Rigid

- Application:Water Supply

- Transport Package:PE Bags+Cartons

Base Info

- Model NO.:PP01

- Trademark:OEM

- Origin:China

- HS Code:39174000

Description

Basic Info.

Model NO. PP01 Trademark OEM Origin China HS Code 39174000Product Description

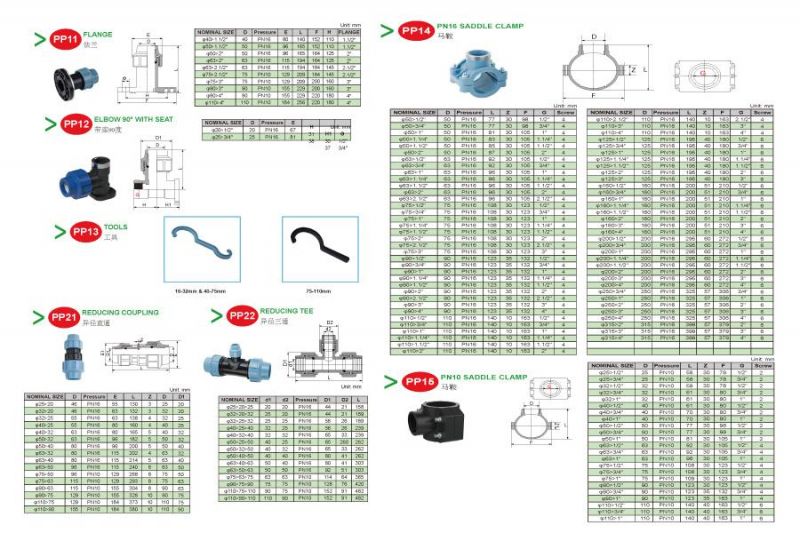

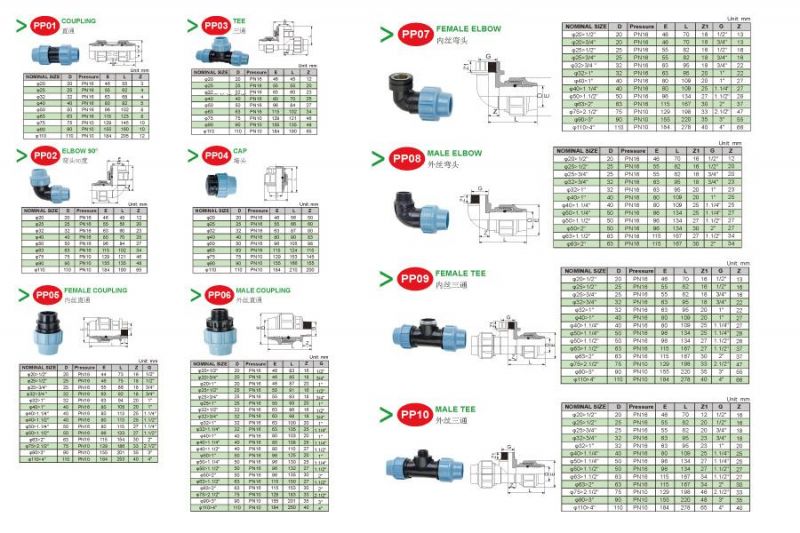

PP Quick Joint Compression Fitting CouplingItem Code:PP01

PRODUCED AS PER DIN STANDARD

FULL RANGE TYPES AND SIZES

BULK QTY CAN BE OEM.

Technical data

| Part | Material |

| Body(A) | Polypropylene co-polymer(PP-B) of exceptional mechanical properties even at high temperature. |

| Blocking bush(D) | Polypropylene |

| Nut(B) | Polypropylene with dye master of high stability to UV rays andsolidity to heat( S grade according to standard DIN54004) |

| Clinching ring(C) | Polyacetal resin(POM)with high mechanical resistance And hardness |

| O Ring gasket(E) | Special elastomeric acrylonitrile rubber(EPDM) for alimentary use |

| Reinforcing ring | AISI 430 (UNI X8Cr17,W,nr 14828)Stainless steel for female threads from 1"to 4" |

WORKING PRESSURES

PP compression fittings allows the maximum working pressure(PN~PFA*) of 16 bar(UNI 9562) for diameters from 16mm to 63mm and PN10 bar for diameters from 75mm to 110mm, at the temperature of 20°C.Maximum allowable working pressures related to the duration of pressure and temperature.

FEATURES

1. Light weight, easy to load and unload

2. Good chemicals and drugs resistance

3. Small resistance to fluidity

4. Strong mechanical strength

5. Good electrical insulation

6. Water quality unaffected

7. Simple installation

APPLICATION

1. Structure Engineering

2. Water supply system

3. for Agriculture Irrigation

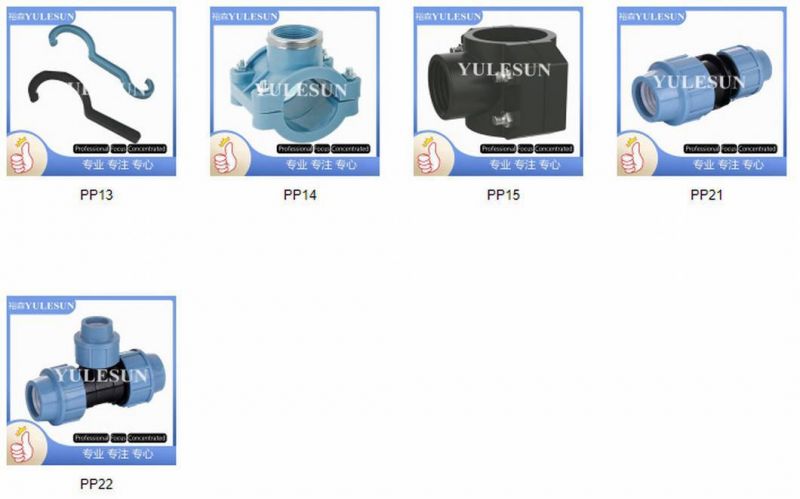

Related products

FAQ: (Frequently Asked Questions)

| 1.What is your MOQ? | Our MOQ is usually 50 CTNS/Size. |

| 2.What is your delievery time? | The time of delievery is around 30-45days. |

| 3.What is your payment terms? | We accept T/T, 100% L/C, or West Union and so on. |

| 4.How about the samples? | we could send you the samples for free, and you need to pay the courier fee. If there are too much samples, then you also need to undertake the sample fee. |

| 5.Why Choose us? | Firstly, comparing with many factories, our prices are more competitive. Secondly, We 100% test working pressure for ALL our products. Finally, After-Sale Services will be highly satisfied. Any problems and feedbacks will be responded efficiently. |

PACKING

DELIVERY

Meet us in Exhibition

Company introduction

We are professional manufacturing for UPVC, CPVC, PPR, PPH etc materials piping systems, and the Compact Ball Valves, Double Union Ball Valves, Foot Valves, Check Valves, Butterfly Valves and its fittings as well. We have more than 30 years experience in Piping and Valves production and sells. Products are provided to domestic and international such as South-East Asia, Middle East, Europe and South America.

Our products confirm to ANSI, BS, DIN, JIS and CNS etc Standards and they are widely used in Agriculture, Chemical, Plating, Purity Application, Potable Water Systems etc involving corrosive fields.

The business philosophy of integrity of GROUP is: Teamwork, Innovation and Gratitude. We are looking forward to Working with you and Growing together!

We have the following advanced:

1. Our R& AMP; D department designs and develops all mould for our products to ensure every mould to be able to achieve best performance during production.

2. We can do any size of the mould as per customers′ request or samples to save developing time for new items.

3. All raw materials are imported to ensure production stability.

4. We have been using the same brand and fixed models for all our raw materials to ensure stability for color, appearance and performance of each batch products.

5. We make high precision fabrication on main bodies of all our True Union Ball Valves by NC machine and ensure accuracy of functional dimensions.

6. All pilot holes shaft onto valve bodies are fabrication precisely to ensure sealing effect.

7. All balls inside valves are fabrication by NC machine to control tolerances within 0.05mm and then using polishing machine to grind so that they are ensured smoothly-switch and leak-proof.

8. All seal rings beside balls are lathed and polishing, so they are perfectly lying on balls, with longer life span and provide good sealing effect.

9. All sockets are processing by NC machine to be ensured coupling tight with 0-Rings.

10. Sealing experiment is processed on all finished valves to ensure them 100% qualified.