Shenzhen in-Sail L4012 M5 Stainless Steel Wire Repair Thread Insert

Shenzhen In-sail Precision Parts Co., Ltd.- Material:Stainless Steel

- Type:Round Head

- Connection:Common Bolt

- Head Style:Round

- Standard:DIN, ANSI, GB, JIS, GOST, BSW, OEM

- Grade:8.8

Base Info

- Model NO.:Metric, Inch, DIN, OEM

- Management System:ISO9001:2008

- Model No.:L4012 Wire Thread Insert

- Finish:Zn,Ni,Tin,Au Plating,Black Oxide,Anodizing,Passiva

- Certification:SGS,RoHS,Material Certication,Ppap

- Delivery Term:by DHL,UPS,TNT,FedEx,EMS,by Ocean,by Air

- Lead Time:5-10 Working Days

- Item Name:Wire Thread Repair Insert

- Transport Package:PE Bag + Cartons, Blister Packing

- Specification:Metric, Inch

- Trademark:In-saiL

- Origin:Shenzhen, China

- HS Code:7318160000

- Production Capacity:100k PCS,Week

Description

Basic Info.

Model NO. Metric, Inch, DIN, OEM Management System ISO9001:2008 Model No. L4012 Wire Thread Insert Finish Zn/Ni/Tin/Au Plating,Black Oxide,Anodizing,Passiva Certification SGS,RoHS,Material Certication,Ppap Delivery Term by DHL,UPS,TNT,FedEx,EMS,by Ocean,by Air Lead Time 5-10 Working Days Item Name Wire Thread Repair Insert Transport Package PE Bag + Cartons, Blister Packing Specification Metric, Inch Trademark In-saiL Origin Shenzhen, China HS Code 7318160000 Production Capacity 100k PCS/WeekProduct Description

Shenzhen In-saiL L4012 M5 Stainless Steel Wire Repair Thread Insert

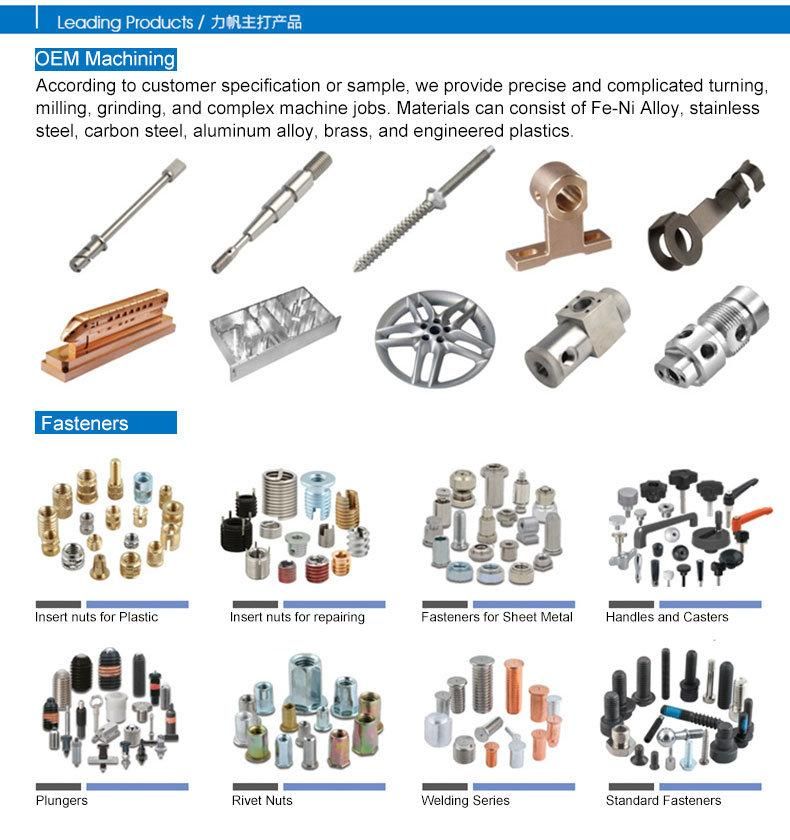

In-saiL is dedicated to manufacturing of precision components and the design, fabrication of

engineering specialty fasteners and fastening solution development.

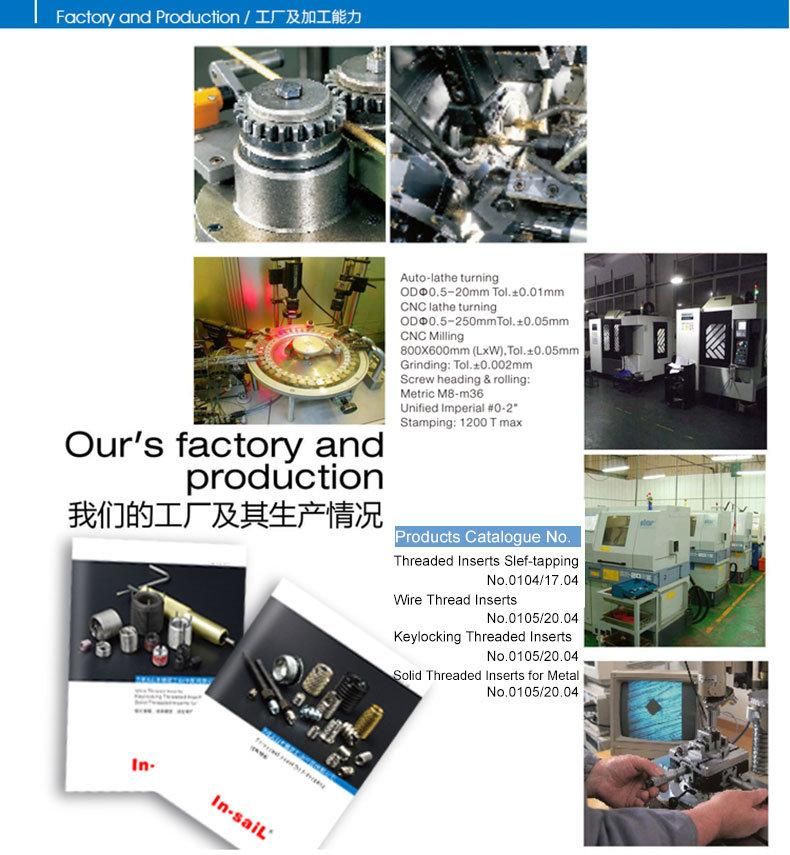

Manufacturing Capability

We have powerful manufacturing capability, our automatic lathes, CNC lathes, CNC machining centers, stamping machines and cold heading machines plus auxiliary equipment like milling machine, grinding machine, EDM and the cooperation of our partners, we are able to support every different components regardless of the prototyping or series production.

|