Smtso-M3-2et, Soldering Smtso Nut

Shenzhen In-sail Precision Parts Co., Ltd.- Material:Brass

- Type:Round Head

- Connection:Press Fit

- Head Style:Round

- Standard:DIN, ANSI, JIS, BSW

- Grade:4.8

Base Info

- Model NO.:SMT,SMD

- Surface Treatment:Zn,Ni,Tin,Au Plating,Black Oxide,Anodizing and So

- Application:Machinery, Chemical Industry, Environmental

- Inspection:100% QC Steps Inspect Before Shipment

- Manufacture Processing:Automatic Lathe,CNC Lathe,Turning

- Materials:Brass; Cuzn39pb3

- Installation Way:SMD,SMT

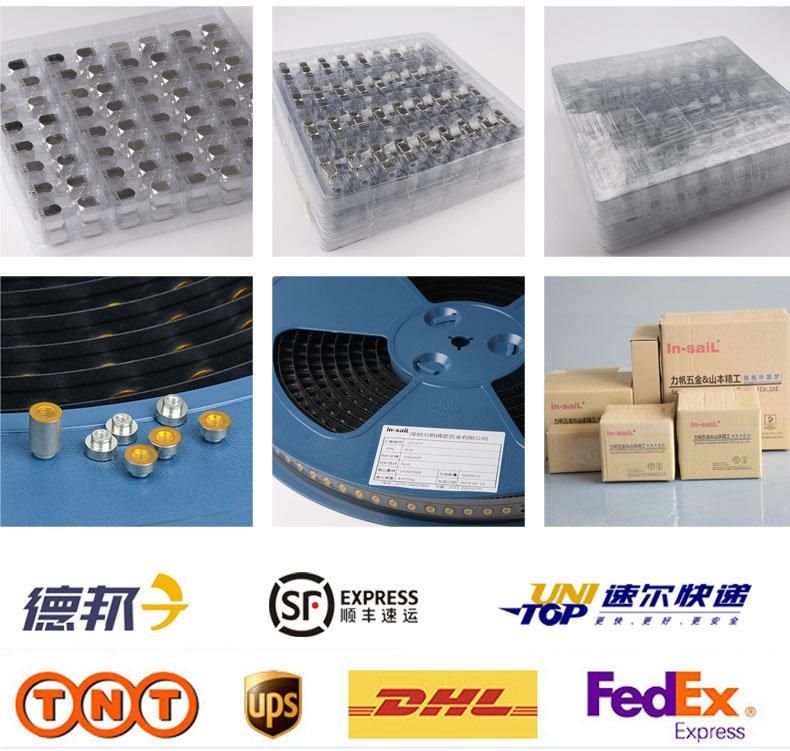

- Transport Package:Bulk; Tape and Reel

- Specification:SGS, Material certification

- Trademark:In-saiL

- Origin:Shenzhen, China

- HS Code:8536904000

- Production Capacity:200000PCS Per Week

Description

Basic Info.

Model NO. SMT/SMD Surface Treatment Zn/Ni/Tin/Au Plating,Black Oxide,Anodizing and So Application Machinery, Chemical Industry, Environmental Inspection 100% QC Steps Inspect Before Shipment Manufacture Processing Automatic Lathe,CNC Lathe,Turning Materials Brass; Cuzn39pb3 Installation Way SMD/SMT Transport Package Bulk; Tape and Reel Specification SGS, Material certification Trademark In-saiL Origin Shenzhen, China HS Code 8536904000 Production Capacity 200000PCS Per WeekProduct Description

Smtso-M3-2et, Soldering Smtso NutIn-saiL is dedicated to manufacturing of precision components and the design, fabrication of engineering specialty fasteners and fastening solution development.Our production covers the fields of industrial electrical and electronic applications, electromedical, telecommunications and automotive equipment.

Manufacturing Capability

We have powerful manufacturing capability, our automatic lathes, CNC lathes, CNC machining centers, stamping machines and cold heading machines plus auxiliary equipment like milling machine, grinding machine, EDM and the cooperation of our partners, we are able to support every different components regardless of the prototyping or series production.

Auto Lathe Turning

The single shaft cam-base automatic lathes are capable of massive production of brass, aluminum alloy, stainless steel components.

Production range: O. D. 0.5-15

CNC Milling

4-axis and 5-axis machining centers are capable of complex structural parts.

Production range: 800X600

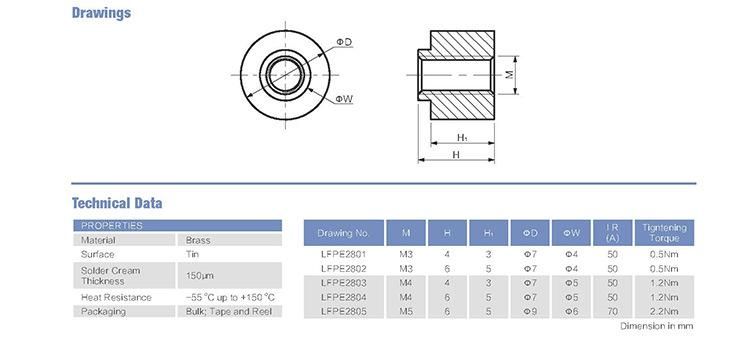

| Materials | Brass C3604,CuZn39Pb3 |

| Surfaces | Tin-plated(stand), further surface such as nickel,Sliver,nickel/gold and other on demand |

| Execution | Press-Fit,Through-hole Reflow,SMT soldeing |

| Dimensions | From 5x5 to 22x22mm, height above PCB from 3mm individuallly |

| Tightening Torque | 2.2Nm; 1.2Nm;9Nm;17Nm; 0.5Nm; 1.6Nm |

| Pin Length | Up to 7.5mm(standard of 3.5mm) |

| Pin diagonal | 1.6mm standrad others on demand |

| Final Hole Diameter | 1.475mm |

| Pins | 6, 8, 10, 12,16,25,36 |

| Operating Temperature | -55ºC up to +150ºC |

| Advantages | 1.Very high ampatity,ideally suited for high continuous and peak currents 2. Press-fit connections show extremely high environmental stability. 3. Low-resistance connection meand low self heating, hence less heat must be dissipated through the system. 4. No heat development on sensitive components and no thermal stress of the circuit board. 5. Extremely stable mechanical 6. No problems with cold solder joints 7. High Mechanical retaining forces 8.Double-sided mounting of circuit board is possible 9. Much higher long-term reliability as for solder connections. 10. More secure than soldering and screw connections 11. No Charges in the production of circuit boards necessary. |

- Pre:DIN Lap Joint Flange

- Next:Marine Forged Flange