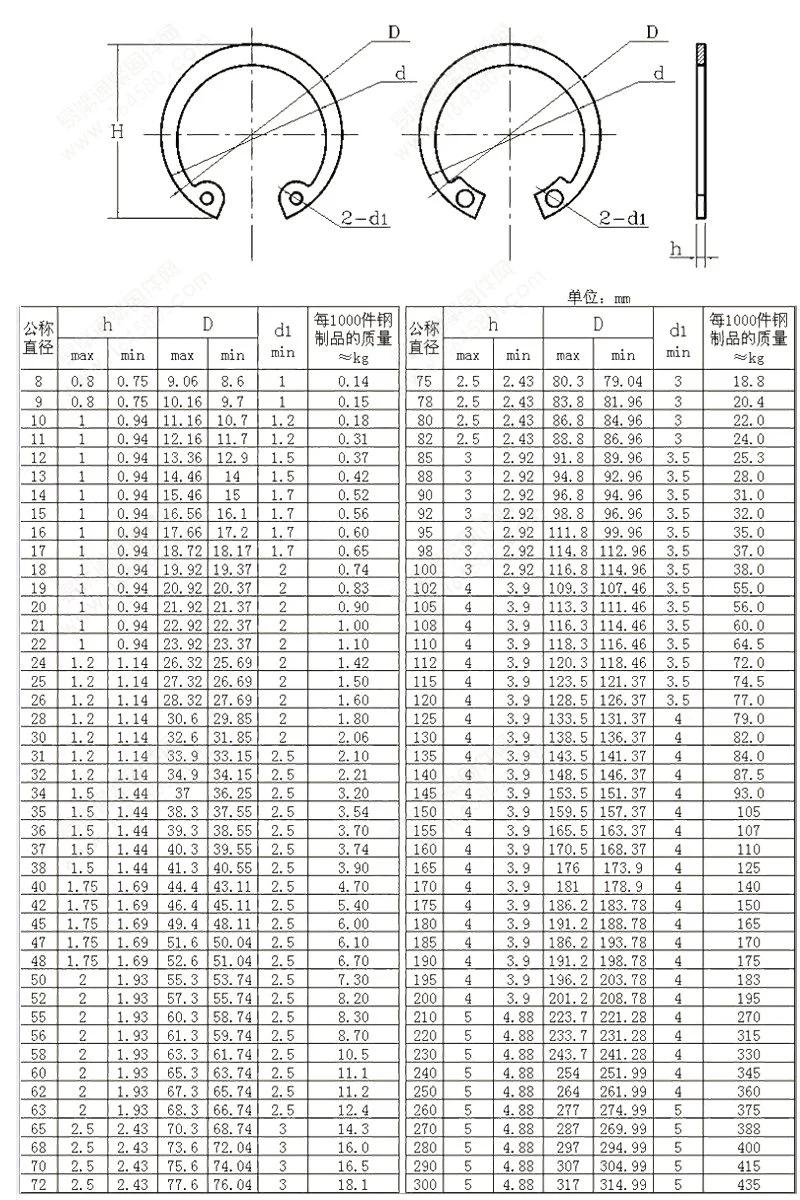

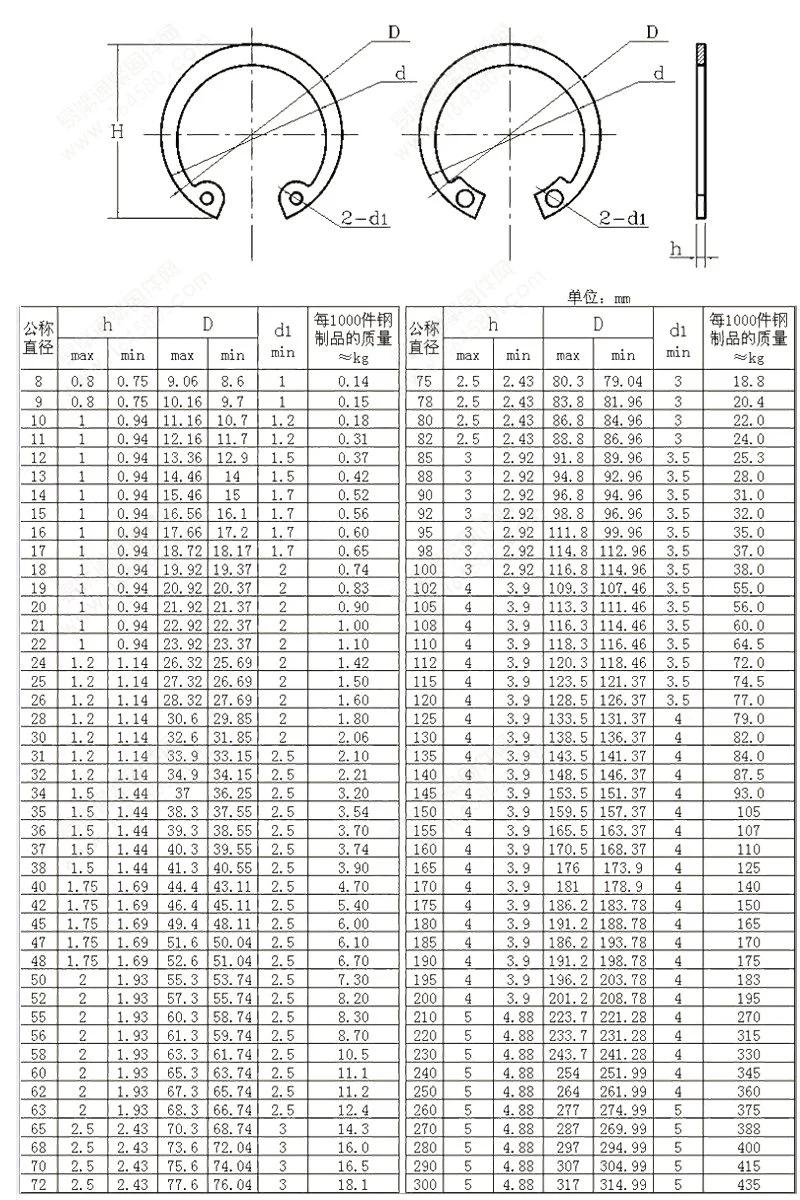

External Retaining Rings Black-Phosphate1060-1090 Spring Steel

Shenzhen In-sail Precision Parts Co., Ltd.- Material:Carbon Steel

- Usage:Automobile

- Surface Finishing:Zinc Plated

- Certification:ISO, RoHS, CE

- Standard:GB,T20057-2006, GB,T883-1986, GB,T884-1986, GB,T885-1986, GB,T886-1986, GB,T891-1986, GB,T892-1986

- Customized:Non-Customized

Base Info

- Model NO.:DIN471 DIN472

- Application:Circlip

- Management System:ISO9001:2008

- Lead Time:5-15 Working Days

- Samples:Welcome

- Delivery Term:by DHL,UPS,TNT,FedEx,EMS,by Ocean,by Air

- Warranty:Replacement at All Our Cost for Rejected Products

- Transport Package:PE Bag + Cartons, Blister Packing

- Specification:ISO, SGS

- Trademark:In-saiL

- Origin:Shenzhen, China

- Production Capacity:100K PCS,Week

Description

Production CapabilityAuto-lathe turning:ODΦ0.5-20mm,Tol.±0.01mm CNC lathe turning:ODΦ0.5-250mm,Tol.±0.005mm CNC Milling:800x600mm(LxW),Tol.±0.05mm Grinding:Tol.±0.002mm Screw heading & rolling:Metric 0.8-M6,Unified Imperial#0-1/4'' Stamping:200T max Lead Time 5-15 working days Samples Welcome Delivery term By DHL,UPS,TNT,FedEx,EMS,By Ocean,By Air Warranty Replacement at all our cost for rejected products

Manufacturing Capability

We have powerful manufacturing capability, our automatic lathes, CNC lathes, CNC machining centers, stamping machines and cold heading machines plus auxiliary equipment like milling machine, grinding machine, EDM and the cooperation of our partners, we are able to support every different components regardless of the prototyping or series production.

Automation Components

Available for a variety of sizes automation components,In-saiL provides solutions to suit any customer

need.

Auto Lathe Turning

The single shaft cam-base automatic lathes are capable of massive production of brass, aluminum

alloy, stainless, steel components. Production range: O.D. 0.5-15.

CNC Milling

4-axis and 5-axis machining centers are capable of complex structural parts.

Production range: 800x600.

Screw Heading & Rolling

The screw production lines finish the cold heading and thread rolling for small carbon steel or stainless

steel screws.

Production range: M0.8-M6 or equivalent sized imperial screws

Stamping

Stamping machines perform the blanking, punching, blending, drawing. Currently we are working on simple stamping jobs.

Production range: 200T max.

Manufacturing Capability

We have powerful manufacturing capability, our automatic lathes, CNC lathes, CNC machining centers, stamping machines and cold heading machines plus auxiliary equipment like milling machine, grinding machine, EDM and the cooperation of our partners, we are able to support every different components regardless of the prototyping or series production.

Automation Components

Available for a variety of sizes automation components,In-saiL provides solutions to suit any customer

need.

Auto Lathe Turning

The single shaft cam-base automatic lathes are capable of massive production of brass, aluminum

alloy, stainless, steel components. Production range: O.D. 0.5-15.

CNC Milling

4-axis and 5-axis machining centers are capable of complex structural parts.

Production range: 800x600.

Screw Heading & Rolling

The screw production lines finish the cold heading and thread rolling for small carbon steel or stainless

steel screws.

Production range: M0.8-M6 or equivalent sized imperial screws

Stamping

Stamping machines perform the blanking, punching, blending, drawing. Currently we are working on simple stamping jobs.

Production range: 200T max.