Clamps 90 Degree Pipe Tube Fittings and Connectors

Shandong Youshang Machinery Equipment Co., Ltd.- Type:Elbow

- Size:as Customers′ Requirements

- Surface Treatment:Galvanizing, Zinc Primer and Painting

- Application:Connect Pipes

- Certificate:SGS

- Technics:Casting

Base Info

- Model NO.:YS fitting

- Packing:Cutomized Color Design Box

- Product Name:Handrail Bracket Wall

- Transport Package:as Customers′ Requirements

- Specification:as customers′ requirements

- Trademark:Youshang

- Origin:China

- HS Code:7218100000

- Production Capacity:10000 Ton,Tons Per Month

Description

Des.

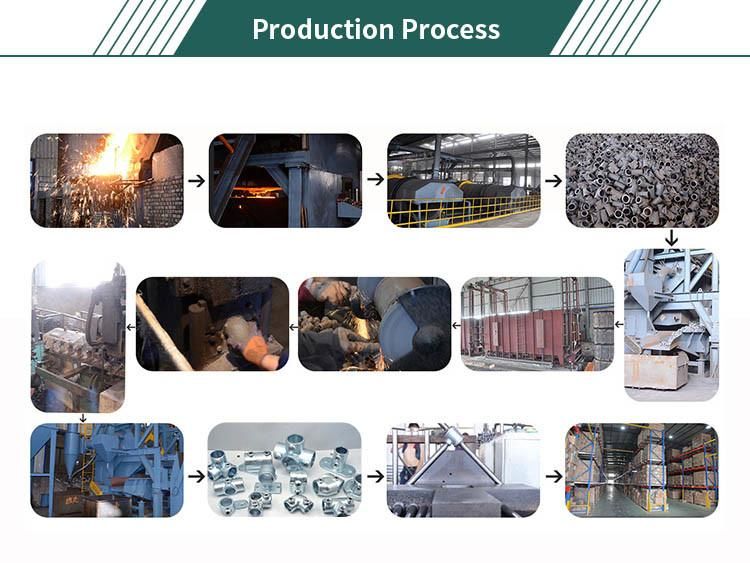

Casted parts/components

Cast method

Sand cast, die cast, Lost foam/wax, investment casting, centrifugal casting,

Processing

Precision CNC machining, grinding, tapping ,painting and assembly

Finish treatment

Tempering , quenching, annealing, normalizing

Surface treatment

-blast shooting

-HDG,zince

-Chrome plating

-Powder coating

-Anodizing

-Polishing

-Electrophoresis

-Electrostatic color paining

QA

Caliper, roughness tester, strength tester, spectrograph, CMM, metalloscope and etc.. 3party inspection report is able to serve as your needs.

Material range

Die casting: Aluminum or alloy A360, A380, A390, ADC12,ADC10,ALSI09 etc.

Ductile iron casting part: QT400 , QT450, QT500, QT550, QT600, QT700

Zinc & Zinc alloy. ZA-3,ZA-5,ZA-8

Sand casting:ZL101,ZL104,ZL102 and so on.

Iron casting: HT150, HT200, HT250, HT300,etc.

Standard: JIS, DIN, ASTM,BS, ISO,AISI

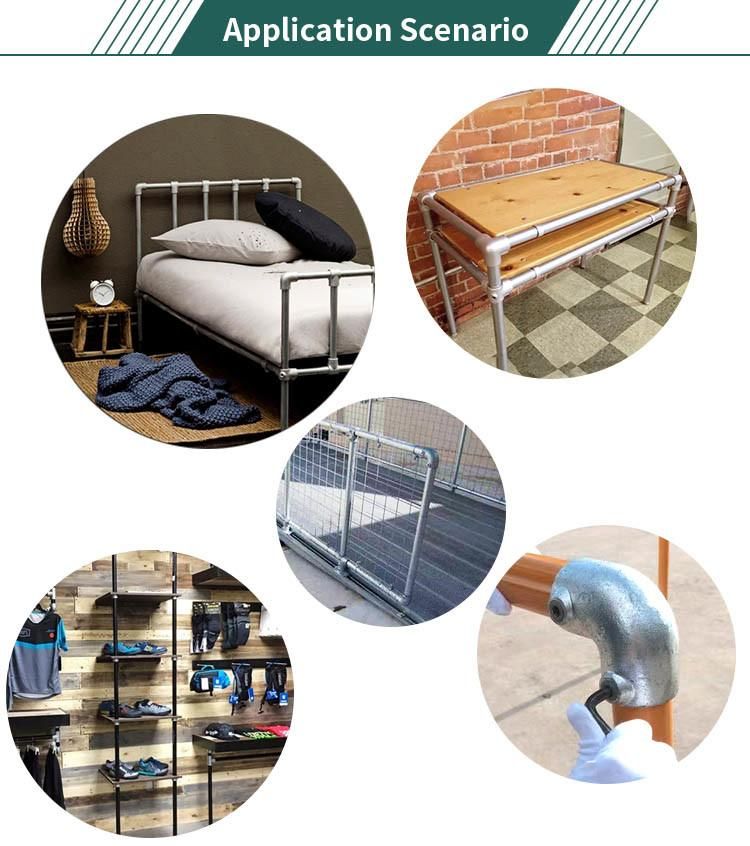

Application scope

-Woodworking hand tools,

-Electrical high voltage fittings,

-Cookware, BBQ grill,

-Pump/valve body or accessories ,

-Drainage grate,

-Construction accessories

Package

Standard seaworthy packing

FOB Port

CN DLC

Standard

ISO,GB,ASTM,BS,JIS,AISI,DIN and etc.

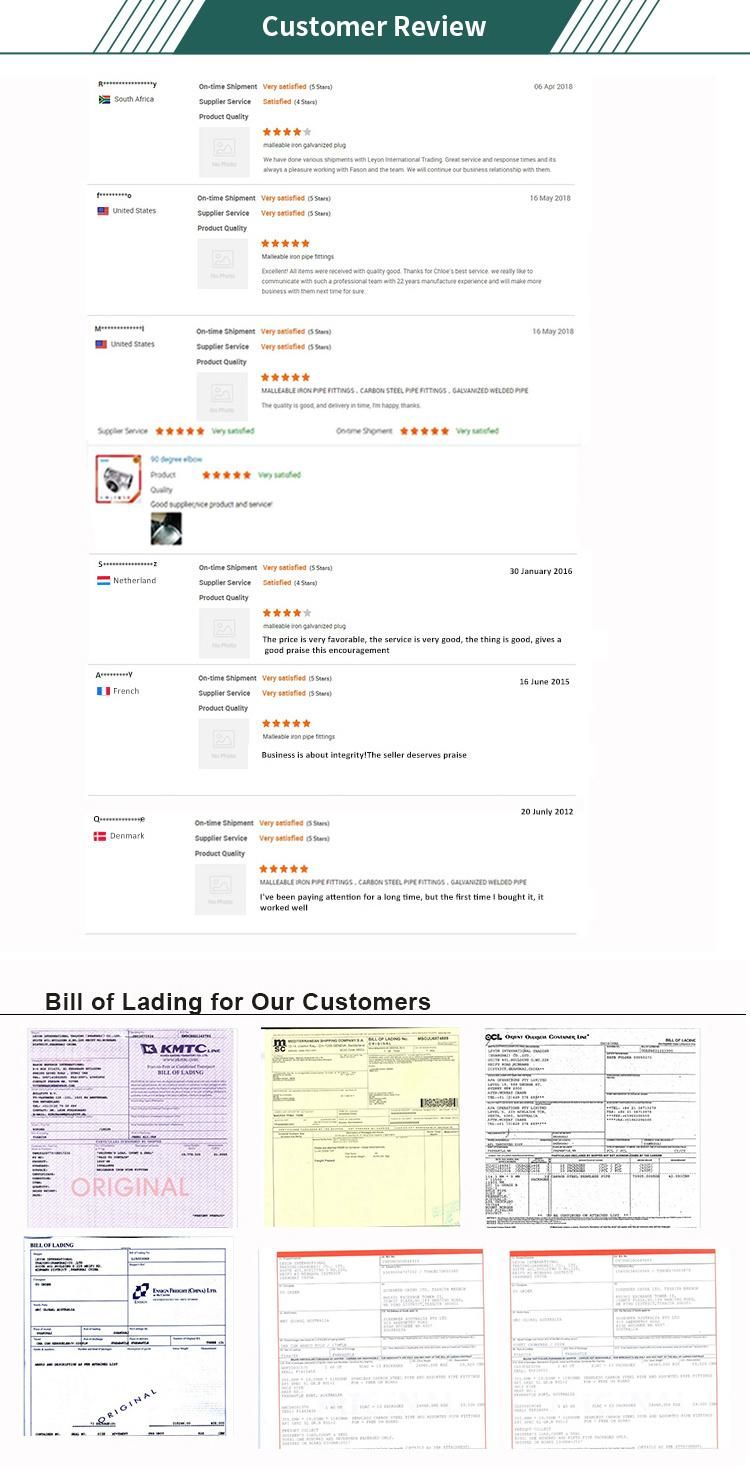

We have very professional trading team,strong Technical R&D dept.,International Inspection dept.,with large producing capacity of pipe fitting, superior quality and first class service.

We have very professional trading team,strong Technical R&D dept.,International Inspection dept.,with large producing capacity of pipe fitting, superior quality and first class service.

FAQ

1: What information does the quotation need?Pls. offer your drawings and/or samples, quantity and packing's requirements. Drawings in PDF, IGS, DWG, STEP, MAX are suitable to us.

2: What's lead time for samples and products?

Lead time for samples: 45days depend on the structure of the part and other requirements on heat treatment, machining, surface treatment and so on. Mass production lead time: 45days depend on products' characteristics and quantity.

3: What is the requirement on payment?

Tooling Cost:100% T/T advanced Payment for the Order:50% deposit,50% to be paid before shipment.

4: What are surface treatments available?

Powder coating, Shoot Blasting, Painting, Polishing, Acid Pickling, Anodizing, Zinc Plating, Hot-dip Galvanizing, Electrophoresis, Chrome Plating

5: What is the packing?

Normal buck packing suitable for shipment by sea and by air. We also organize packing according to customers' requirements.