M12 Hexagon Twin-Headed Joint Bolt with Nut for Busduct System

Suzhou Kiande Electric Co., Ltd.- Material:Carbon Steel

- Type:Hexagon Head

- Connection:Common Bolt

- Head Style:Hexagonal

- Standard:GB

- Grade:12

Base Info

- Model NO.:KDEQ-03-020

- Application:Busbar Joint

- Finish:Hot Galvanizing

- Custom:We Can Customize as Required

- Transport Package:Carton or Polywood Case

- Specification:M12*115, M12*120, M12*130, M12*140

- Trademark:Kiande

- Origin:China

- HS Code:7318151001

- Production Capacity:500000pieces Per Month

Description

Basic Info.

Model NO. KDEQ-03-020 Application Busbar Joint Finish Hot Galvanizing Custom We Can Customize as Required Transport Package Carton or Polywood Case Specification M12*115, M12*120, M12*130, M12*140 Trademark Kiande Origin China HS Code 7318151001 Production Capacity 500000pieces Per MonthProduct Description

Busbar machine busbar accessory / Double head bolt / Double head nut with required torque forceHexagon double head bolt with nut, Shear head bolt M12

1. Material: carbon steel;

2. 3C compliant;

3. Used for connection of busbar joints;

4. Surface treatment: galvanized

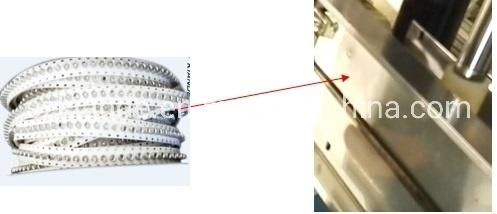

Twin-headed joint bolt proposal:

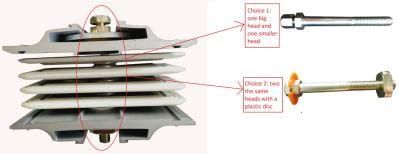

Twin-headed joint nut proposal:

We are the company specialized in busbar machine.Busbar machine means busbar production machine or busbar processing machine including mylar sleeve forming machine, busbar assembly machine, busbar riveting machine, busbar testing & inspection machine, busbar packing machine and busbar conveying machine. If you want to know how we use the machine to assemble the busbar, please kindly get the referenced pictures as below.

Step 1 Prepare all busbar finished components

Step 2 Use related busbar machines to process the busbar

Busbar machine copper processing

Need Kiande's busbar gas-hydraulic copper bar punching machine(This is one-time punching forming. In the market, some busbar manufacturer buys three-in-one busbar machine to bend and punch copper or aluminum bar. As the bar experiences many procedures, the accuracy is not good which will cause the phase distance too small to cause the short circuit.)

Busbar machine mylar sleeve processing machine polyester film forming machine

Need Kiande's mylar/polyester film forming machine. In the market, some busbar manufacturer requests workers to wrap the bar manually. Different workers have different workmanship. If employer meets the inexperienced workers, the wrapping part will have some gaps which will cause the short circuit.

Busbar machine busbar accessory 3M insulation film Conductor(Copper bar/Aluminum bar) end wrapping

Busbar machine busbar accessory Aluminum profile capped casting capped end

Busbar machine Busbar riveting machine

Busbar machine busbar inspection machine busbar testing machine

Busbar machine busbar packing machine busbar packaging machine

Busbar machine busbar accessory rivet the rivet is to connect the profiles instead of bolts more stable and strengthen