| SME B16.5 EN 1092 1 Blind pn10 Flange Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|

| EN 1092 1 Blind pn10 Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ASME Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ASME B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

|---|

| EN 1092 1 Blind pn10 Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

|---|

| EN 1092 1 Blind pn10 Flange Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

|---|

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

|---|

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

|---|

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

|---|

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

|---|

| Most common types of EN 1092 1 Blind pn10 Flange | Forged / Threaded / Screwed / Plate |

|---|

| Test Certificates | EN 10204/3.1B

Raw Materials Certificate

100% Radiography Test Report

Third Party Inspection Report, etc |

|---|

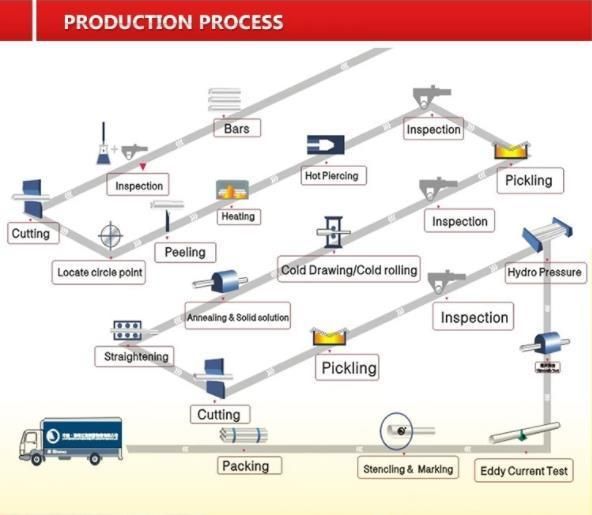

| Production technique | - Forged, Heat treated and machined

|

|---|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, , Groove |

|---|

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS

15 NB (1/2") to 200 NB (8")

Equal and Reducing Configurations |

|---|

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

|---|

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

|---|

| Manufacturer of | ASME DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

EN 1092 1 Blind pn10 Flange: -BS Flange, EN Flange, API 6A Flanges, ASME Flanges, ASME Flanges, DIN Flanges, EN1092-1 Flanges, UNI Flanges, JIS/ KS Flanges, BS4504 Flanges, GB Flanges, AWWA C207 Flanges, GOST Flanges, PSI Flangse - B.S: BS4504 , BS3293, BS1560, BS10

- AS 2129: Table D; Table E; Table H

- ASME B16.5, ASME B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

- ASME : ASME B16.5, ASME B16.47(API605), MSS SP44, ASME B16.36, ASME B16.48

- ASME B16.5, ASME B16.47, MSS SP44, ASME B16.36, ASME B16.48

- American standard (ANSI)

- German (DIN)

- British standard (BS)

- DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 EN 1092 1 Blind pn10 Flange

- The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276

|

|---|

| EN 1092 1 Blind pn10 Flange Uses & application | - Bitumen upgraders.

- Heavy oil refineries.

- Nuclear power (mostly seamless).

- Petrochemicals and acids.

|

|---|

| Carbon Steel EN 1092 1 Blind pn10 Flange | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Stainless Steel EN 1092 1 Blind pn10 Flange | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Alloy Steel EN 1092 1 Blind pn10 Flange | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium EN 1092 1 Blind pn10 Flange | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7

ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Copper EN 1092 1 Blind pn10 Flange | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel EN 1092 1 Blind pn10 Flange | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Brass EN 1092 1 Blind pn10 Flange | 3602 / 2604 / H59 / H62 / etc. |

| Inconel EN 1092 1 Blind pn10 Flange | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 EN 1092 1 Blind pn10 Flange |

| Hastelloy EN 1092 1 Blind pn10 Flange | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Monel EN 1092 1 Blind pn10 Flange | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 EN 1092 1 Blind pn10 Flange | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium EN 1092 1 Blind pn10 Flange | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel EN 1092 1 Blind pn10 Flange | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Duplex EN 1092 1 Blind pn10 Flange | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex EN 1092 1 Blind pn10 Flange | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy EN 1092 1 Blind pn10 Flange | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

| 254 Smo EN 1092 1 Blind pn10 Flange | ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic EN 1092 1 Blind pn10 Flange | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Other EN 1092 1 Blind pn10 Flange material | Tin bronze, Alumunum bronze, Lead bronze |