Anti-Seismic Support and Hanger

KUNSHAN MAX CLEANROOM SYSTEM CO., LTD.- Standard:GB

- Material:Carbon Steel Q235, Ss

- Connection:Screw, Nut

- Surface Treatment:Hot-DIP Galvanized, Post-Galvanized

- Head Type:C-Type

- C-Type Steel Material:Carbon Steel, Ss

Base Info

- C-Type Steel Thickness:1.5mm, 2.0mm, 2.5mm, 2.75mm, 3.0mm

- Length:3000mm, 6000mm

- Surface Finishing:Hot-DIP Galvanized, Post-Galvanized

- C-Type Steel:with Holes, Without Holes

- Transport Package:Pallet, Container

- Specification:According to URS

- Trademark:MAX

- Origin:China

- HS Code:7308900000

- Production Capacity:200, 000 Sets,Year

Description

Basic Info.

C-Type Steel Thickness 1.5mm, 2.0mm, 2.5mm, 2.75mm, 3.0mm Length 3000mm, 6000mm Surface Finishing Hot-DIP Galvanized, Post-Galvanized C-Type Steel with Holes, Without Holes Transport Package Pallet, Container Specification According to URS Trademark MAX Origin China HS Code 7308900000 Production Capacity 200, 000 Sets/YearProduct Description

Production Description:

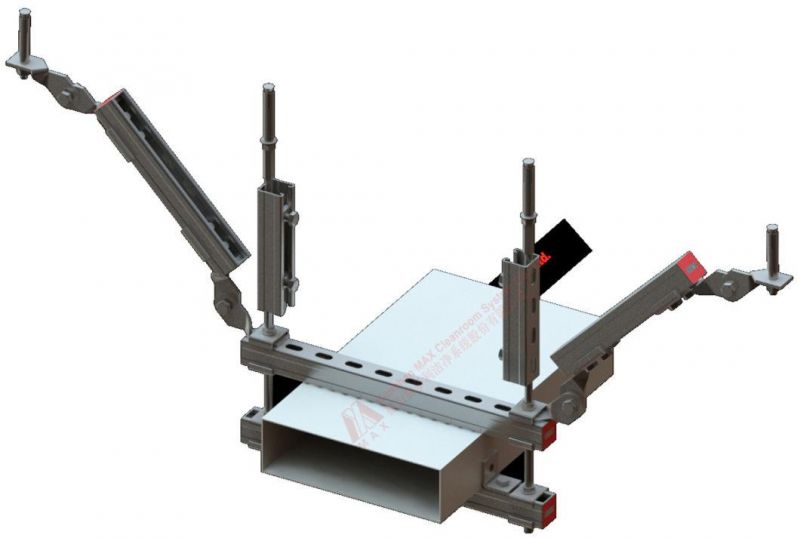

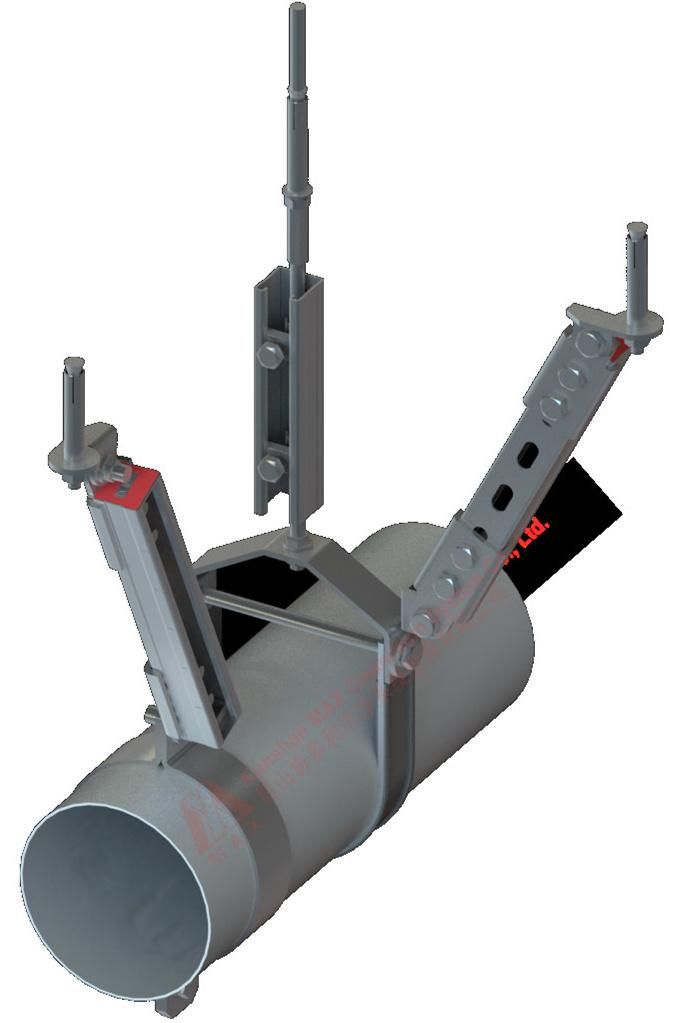

The finished support and hanger system consists of C-type steel and various connectors, which are directly produced by manufacturer in factory and then assembled by construction personnel at site.

MAX Cleanroom provides threaded rod type support and hanger system, integrated support and hanger system and several anti-seismic support and hanger systems. These support and hanger systems are widely used in water supply and drainage, HVAC system, electrical system, solar photovoltaic system, subway engineering and other construction disciplines.

During earthquake the damage of building and electromechanical equipment (fire-fighting pipelines, sprinkler system, smoke exhaust system, electrical system, etc.) will directly lead to the failure of fire-fighting function. Fire, smoke and other secondary disasters caused by this reason will greatly increase the number of casualties. The number of casualties might even more than that caused by the collapse of buildings and other direct disasters. The anti-seismic support and hanger system will effectively protect the electromechanical system during the earthquake, so as to ensure the quick recovery of the working state after the earthquake.

Features:

- Reliable bearing capacity;

- Convenient for installation and maintenance;

- Good versatility and combination performance: It ensures the convenience, applicability and safety of various support and hanger system under different conditions;

- Professional installation and assembly solutions;

- Flexible and adjustable installation position: Ensure the cross operation of all disciplines at site, which can be adjusted later;

- Good compatibility of all disciplines which can help to save space;

- Reduce the occurrence of secondary disasters caused by earthquakes;

- Effectively protect the electromechanical system during the earthquake;

| No. | Item | Specification |

| 1 | Product No. | MAX-CH-K |

| 2 | Product type | Anti-seismic support and hanger system |

| 3 | Main components | C-Type steel, expansion bolt, connectors, screw, flange nut |

| 4 | C-Type Steel | Carbon steel Q235, SS |

| 5 | Treatment | Hot-Dip Galvanized, post-galvanized |

| 6 | Brand | MAX Cleanroom |

| 7 | C-Type Steel Thickness | 1.5mm, 2.0mm, 2.5mm, 2.75mm, 3.0mm |

| 8 | C-Type Steel Height | 21mm, 41mm, 62mm, 72mm |

| 9 | C-Type Steel Width | 41mm |

| 10 | C-Type Steel Length | 3000mm, 6000mm |

3D Rendering:

Kunshan MAX Cleanroom System Co., Ltd is a state-owned holding company. It's the leading total solution supplier for cleanroom system, which is able to provide design service, R&D, manufacturing, installation and after-sales services for pharmaceutical, aerospace, electronics, food processing, cosmetics, new energy and other industries.

Founded in 2000 year, MAX has become the largest clean room supplier in China after nearly 20 years of development. In China, MAX has 4 production bases, 5 factories and 8 production lines in Kunshan, Changzhou, Suzhou and Chengdu, including one automatic production line in Changzhou. The total annual production capacity of sandwich panels can reach 4 million square meters. In addition, its subsidiary TECO in Italy provides high-end products and services.

MAX has its own R&D department and independent laboratory. So far, it has been awarded 42 national patents. In China, MAX has served more than 1000 customers, including many multinational companies, such as Abbott, Otsuka, Baxter, BI, GSK, Bayer, Fresenius, Novartis, AstraZeneca, Roch, Pfizer, Merck, MSD, Johnson&Johnson, Sanofi-Aventis, Eisai, Daiichi Sankyo and so on.

Since 2012, MAX successfully entered the international market and has completed more than 90 projects in almost 40 countries, including some EPC projects. With the guiding principle of "Innovating and Improving for Perfection", MAX has established long-term and solid cooperation with many foreign customers.

Our Workshop:

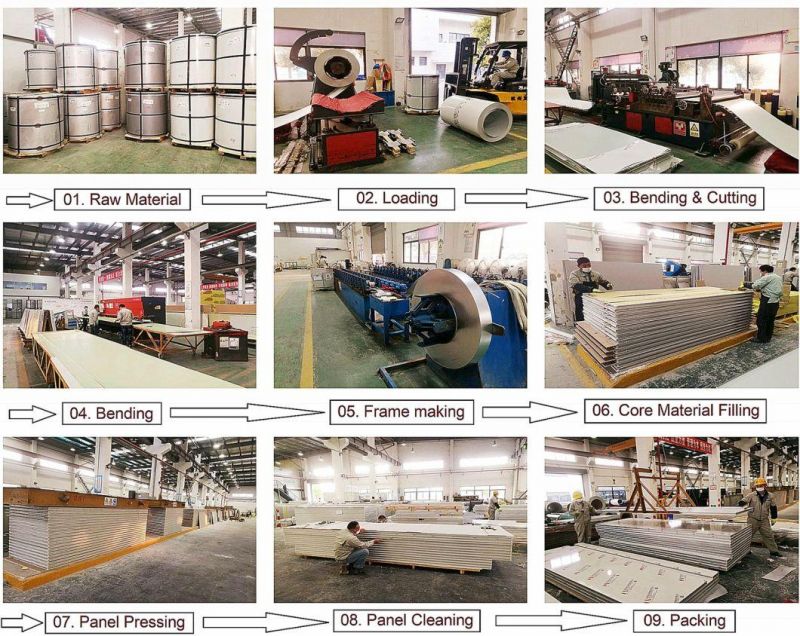

Production Process:

Automatic Production Line:

Our Key Clients:

Our Mission:

Serve National Strategy;

Boost Technical Innovation;

Achieve Employees' Dream.

Business Philosophy:

Client Focus

Service First

Contact Information:

Kunshan MAX Cleanroom System Co., Ltd.

Add: No.177, Huayang Road, Lujia Town, Kunshan City, Jiangsu Province, P.R.China

Website: ksmax-cleanroom.en.made-in-china.com; ksmax-cleanroom.en.made-in-china.com (English)