China Supplier Forging En1092 Slip on Pn 16 Plate Flange

Shanxi Baite Fluid Machinery Co., Ltd.- Standard:ANSI, DIN, JIS, En1092

- Type:Slip on Flange

- Material:Carbon Steel

- Structure:Flanges

- Connection:Flanged

- Sealing Surface:RF

Base Info

- Model NO.:slip on flange BTF-FL-021

- Manufacturing Way:Forging

- Shipment Term:by Sea or by Air

- Pressure:150lbs-2500lbs

- Carbon Steel Flange:A105 A105n Q235 St37.2

- Stainless Steel Flange:Ss316 Ss316L Ss304 Ss304L

- Alloy Steel Flange:16mo3 13crmo4-5 15CrMo

- Surface:Painting or Rust Oil

- Quality Control:TUV SGS

- Quality Certificate:Material Test Report Dimension Report

- Certificate:Forma Forme Co

- Name:Forging En1092 Slip on Pn 16 Plate Flange

- Transport Package:Ply Wooden Cases or Pallet

- Specification:1,2"-80"

- Trademark:BTF or as request

- Origin:China

- HS Code:73079100

- Production Capacity:100 Tons Per Month

Description

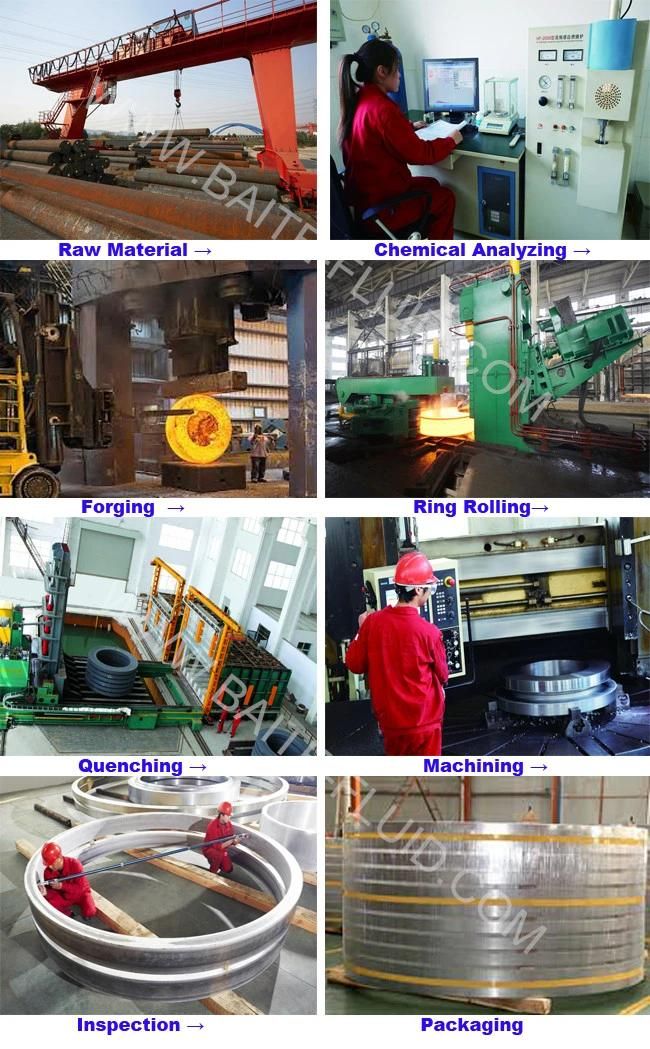

Production Process

Equipment Exhibition

Product Show

threaded flange

Threaded Flanges are also known as screwed flange, and it is having a thread inside the flange bore which fits on the pipe with matching male thread on the pipe. This type of joint connection is Speedy and simple but not suitable for high presser and temperature applications. Threaded Flanges are mostly used in utility services such as air and water.

Blind Flanges

The blind flange is a blank disc with bolt hole. These types of flanges are used with another type of flange to isolate the piping system or to terminate the piping as an end. Blind flanges are also used as a manhole cover in the vessel.

Slip on flanges

Slip-On flange has a hole with matching outside diameter of pipe from which pipe can pass. The flange is placed on pipe and fillet welded from both inside and outside. Slip-On Flange is suitable for low pressure and temperature application. This type of flange is available in large size also to connect big bore piping with storage tank nozzles. Normally, these flanges are of forged construction and are provided with the hub. Sometimes, these flanges are fabricated from plates and are not provided with the hub.

Weld neck flange

Weld neck flange are most widely used flanged in process piping. It gives the highest level of joint integrity due to Butt-welded with a pipe. These types of flanges are used in high pressure and temperature application. Weld neck flanges are Bulky & costly with respect to other types of flange.

Quality Assurance

Quality System Certificate:

We have Grade A Manufacture License of Special Equipment , Press Equipment Directive Quality-Assurance System Certificate , China Classification Society Certificate of Work Approval, TUV Certificate

Perfect Inspection Process:

Raw material inspection(5steps)- Raw materials testing is to ensure the raw material conforming to the order requirements.

Process testing(10steps)-Each processing step testing is to guarantee each step product qualified.

Factory testing(6steps)-Assure 100% product qualified rate to meet customer's requirements

Contact Us

All products can be customerized designed . We will supply professional service within 24 hours .Welcome to contact .

Sales network