Carbon Steel Exhaust DIN Flange

Shanxi Baite Fluid Machinery Co., Ltd.- Standard:ANSI, DIN, GB, JIS, GOST, En1092

- Type:Flat Flange

- Material:Stainless Steel

- Structure:Flanged

- Connection:Welding

- Sealing Surface:RF

Base Info

- Model NO.:din flange BTF-FL-044

- Manufacturing Way:Forging

- Name:Carbon Steel Exhaust DIN Flange

- Shipment Term:by Sea or by Air

- Surface:Rust Oil or Painting

- Pressure:150lbs-2500lbs

- Quality Control:TUV SGS

- Quality Certificate:Material Test Report Dimension Report

- Certificate:Forma Forme Co

- Carbon Steel Flange:A105 A105n Q235 St37.2 16mn 20mn 20# Steel C22.8

- Stainless Steel Flange:Ss316 Ss316L SS304 Ss304L

- Alloy Steel Flange:16mo3 13crmo4-5 15CrMo P250gh

- Transport Package:Ply Wooden Cases or Pallet

- Specification:1,2"-80"

- Trademark:BTF or as request

- Origin:China

- HS Code:73079100

- Production Capacity:100 Tons Per Month

Description

Carbon steel :

ASTM A105, ASTM A350 LF1,LF2,S235JR,P245GH,C22.8,P250GH,P280GH,16MN,20#steel.

Stainless steel :

ASTM A182 F304/304L,F316/316L.

Alloy steel :

ASTM A182 F11,F12,16Mo3,13CrMo4-5,15CrMo,1.7335.

Inspection

factory inspection in workshop , the third party inspection SGS,3.1 certificate , MTC etc.

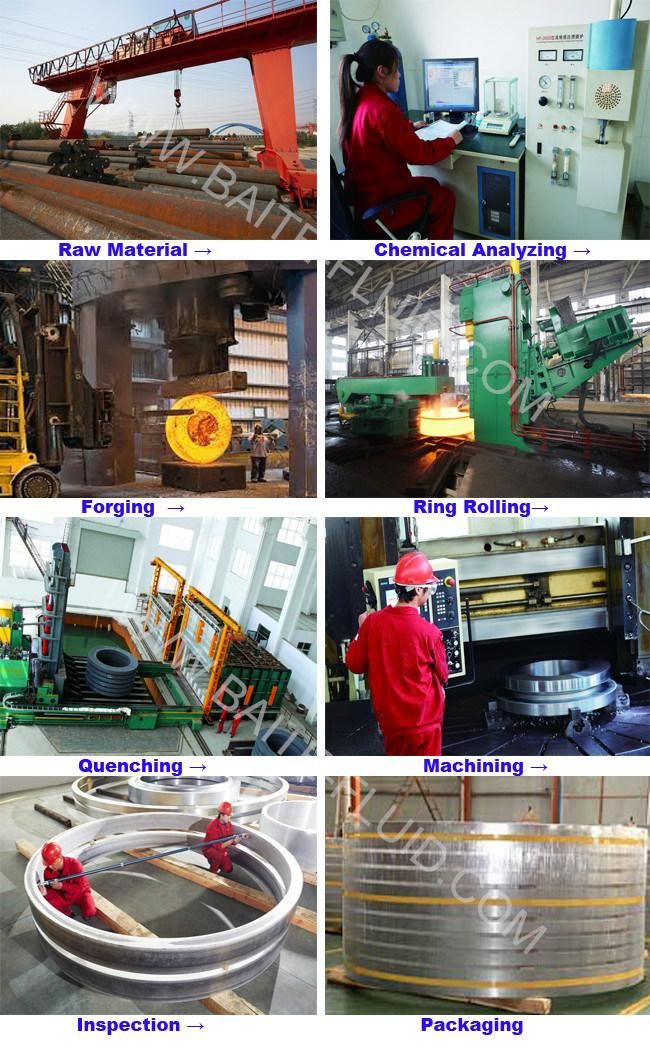

Production Process

Equipment Exhibition

Product Show

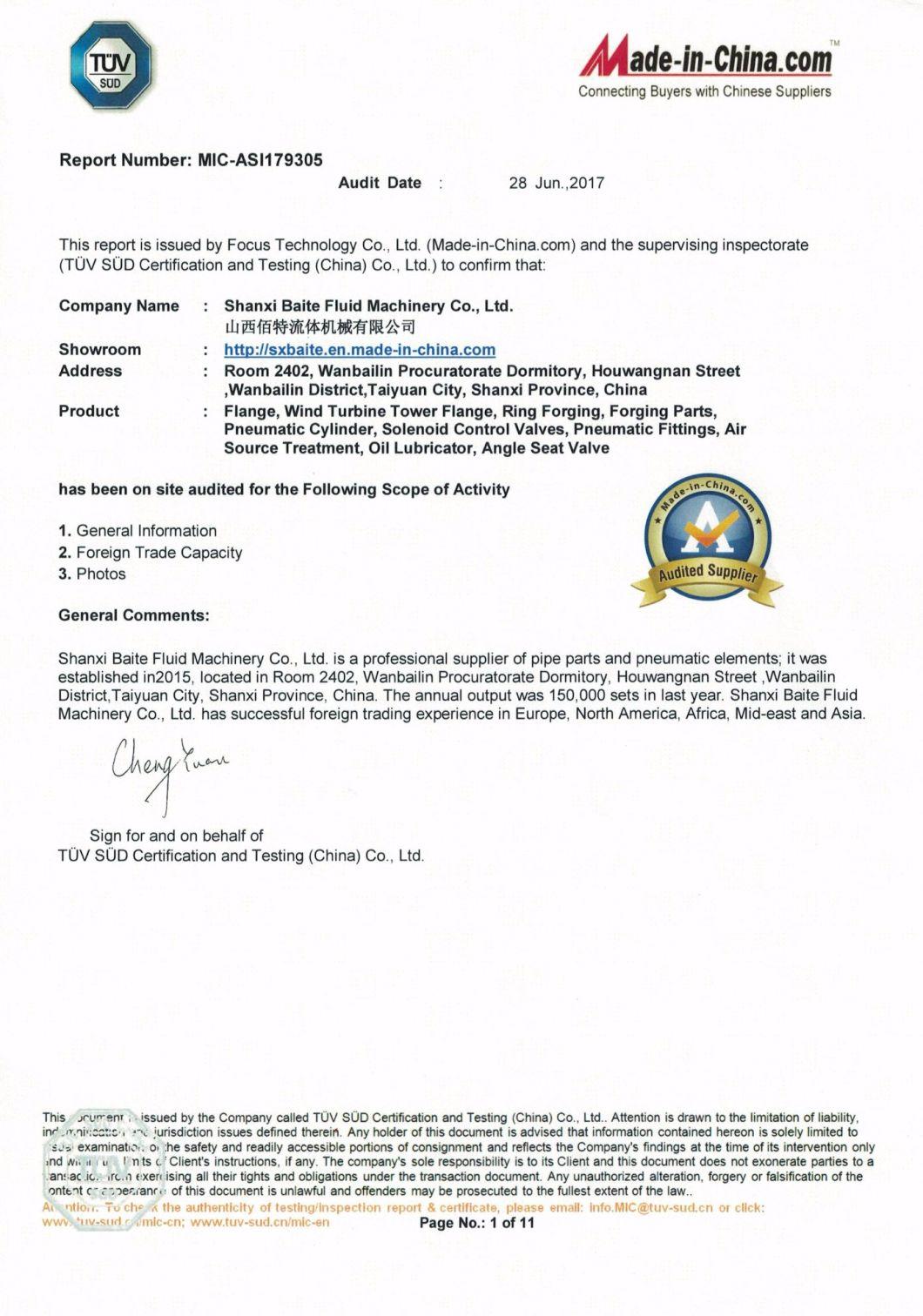

Quality Assurance-TUV Certificate

Quality System Certificate:

We have Grade A Manufacture License of Special Equipment , Press Equipment Directive Quality-Assurance System Certificate , China Classification Society Certificate of Work Approval, TUV Certificate

Perfect Inspection Process:

Raw material inspection(5steps)- Raw materials testing is to ensure the raw material conforming to the order requirements.

Process testing(10steps)-Each processing step testing is to guarantee each step product qualified.

Factory testing(6steps)-Assure 100% product qualified rate to meet customer's requirements

Contact Us

All products can be customerized designed . We will supply professional service within 24 hours .Welcome to contact Sales Director Cathy Liu .