Integrated Support and Hanger for Cleanroom

KUNSHAN MAX CLEANROOM SYSTEM CO., LTD.- Standard:GB

- Material:Carbon Steel Q235, Ss

- Connection:Screw, Nut

- Surface Treatment:Hot-DIP Galvanized, Post-Galvanized

- Head Type:C-Type

- C-Type Steel Material:Carbon Steel, Ss

Base Info

- C-Type Steel Thickness:1.5mm, 2.0mm, 2.5mm, 2.75mm, 3.0mm

- Length:3000mm, 6000mm

- Surface Finishing:Hot-DIP Galvanized, Post-Galvanized

- C-Type Steel Type:with Holes, Without Holes

- Transport Package:Pallet, Container

- Specification:According to URS

- Trademark:MAX

- Origin:China

- HS Code:7308900000

- Production Capacity:200, 000 Sets,Year

Description

Basic Info.

C-Type Steel Thickness 1.5mm, 2.0mm, 2.5mm, 2.75mm, 3.0mm Length 3000mm, 6000mm Surface Finishing Hot-DIP Galvanized, Post-Galvanized C-Type Steel Type with Holes, Without Holes Transport Package Pallet, Container Specification According to URS Trademark MAX Origin China HS Code 7308900000 Production Capacity 200, 000 Sets/YearProduct Description

Kunshan MAX Cleanroom System Co., Ltd is a state-owned holding company. It's the leading total solution supplier for cleanroom system, which is providing design service, R&D, manufacturing, installation and after-sales services for pharmaceutical, aerospace, electronics, food processing, cosmetics, new energy and other industries.

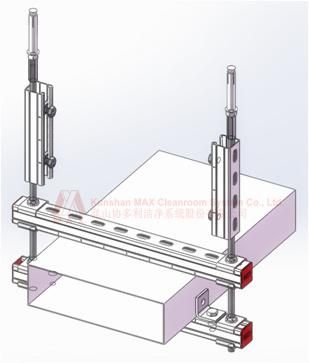

The finished support and hanger system consists of C-type steel and various connectors, which are directly produced by manufacturer in factory and then assembled by construction personnel at site.

MAX Cleanroom provides threaded rod type support and hanger system, integrated support and hanger system and several anti-seismic support and hanger systems. These support and hanger systems are widely used in water supply and drainage, HVAC system, electrical system, solar photovoltaic system, subway engineering and other construction disciplines.

- Reliable bearing capacity;

- Convenient for installation and maintenance;

- Good versatility and combination performance: It ensures the convenience, applicability and safety of various support and hanger system under different conditions;

- Professional installation and assembly solutions;

- Flexible and adjustable installation position: Ensure the cross operation of all disciplines at site, which can be adjusted later;

- Good compatibility of all disciplines which can help to save space;

| No. | Item | Specification |

| 1 | Product No. | MAX-CH-C |

| 2 | Product type | Integrated support and hanger system |

| 3 | Main components | C-Type steel, expansion bolt, connectors, screw, flange nut |

| 4 | C-Type Steel | Carbon steel Q235, SS |

| 5 | Treatment | Hot-Dip Galvanized, post-galvanized |

| 6 | Brand | MAX Cleanroom |

| 7 | C-Type Steel Thickness | 1.5mm, 2.0mm, 2.5mm, 2.75mm, 3.0mm |

| 8 | C-Type Steel Height | 21mm, 41mm, 62mm, 72mm |

| 9 | C-Type Steel Width | 41mm |

| 10 | C-Type Steel Length | 3000mm, 6000mm |

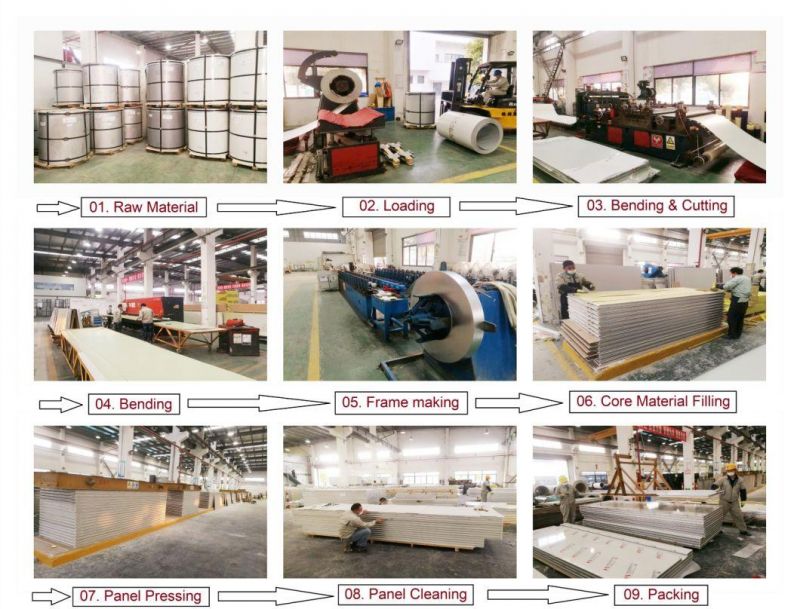

MAX has four production bases around the world, in Kunshan, Chengdu, Changzhou and Italy.

There are eight panel production lines, including one auto production line, sandwich panel production capacity can reach 4,000,000 m2/year.